developments

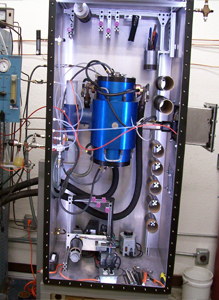

2500°C Continuous Fiber Heat Treatment Furnace

Now up and running and being upgraded daily, our furnace allows for heat treatment of fibers under varying conditions. Different types of line speeds, gases, and temperatures available for processing

Technologies

Structural Ceramic Fibers

MATECH is developing structural ceramic fibers from silicon carbide, silicon nitride/carbide, silicon oxycarbide, tantalum carbide, and hafnium carbide.

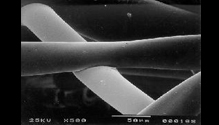

Preceramic polymer derived "green" fiber is produced and wound continuously, as illustrated above. MATECH's control over the rheological behavior of its preceramic polymers allows for easy melt-spinning.

Fiber Mat Strength and Ridigity

MATECH preceramic polymer technology allows fiber mat to be bonded together at the fiber cross-over points to enhance rigidity prior to curing. After curing, the initially thermoplastic preceramic polymer has been converted into a rigid thermoset polymer. At this stage, the preceramic polymer fiber mat can be heat treated to convert it into a ceramic.

Porous Ceramic Filters

MATECH has developed methods of producing low cost, high temperature ceramic filter fabrication. MATECH continuous ceramic paper mat process permits control over fiber diameter, fiber volume fraction, permeability, and thickness.

Ultra High Temperature CMC Components

MATECH has developed high temperature CMC components of all kinds of varying shapes and sizes. MATECH makes C(f)/ZrOC(m), as well as braided C(f)/HfC(m) CMC's such as the Diverter Thruster above.